What is particle size and what does it represent in inorganic powder materials?

What is particle size?

Particle size, as the name suggests, refers to the size of a single powder particle. However, since powder is an aggregate of countless particles, these particles are usually not all the same size. Therefore, in practical industry and scientific research, the concept of "particle size" typically encompasses three aspects:

1.Particle size: Refers to the linear scale of the space occupied by a single particle, usually expressed in diameter (micrometers (µm) or nanometers (nm)).

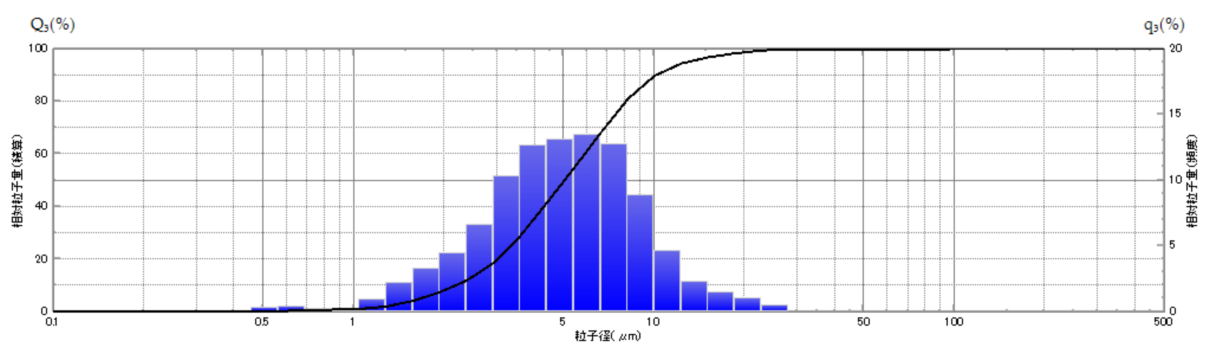

2.Particle size distribution: Refers to the proportion or frequency of particles of different sizes in a powder sample. This is a more important concept than the single "average particle size," and is called "particle size distribution."

3.Characteristic methods: Due to the irregular shape of particles, different measurement methods yield different meanings for "particle size." Common methods include:

Equivalent volume diameter: The diameter of a sphere with the same volume as the particle (commonly used in laser methods).

Equivalent settling diameter: The diameter of a sphere with the same settling velocity as the particle under the same conditions.

Sieve diameter: The width of the smallest square-aperture sieve through which particles can pass.

Measuring instruments: Laser particle size analyzer (most commonly used), sedimentation particle size analyzer, image-based particle size analyzer, nanoparticle size analyzer (dynamic light scattering method), sieving machine, etc.

What does particle size represent in inorganic powder materials?

Particle size and its distribution are among the decisive factors determining the processing performance, application performance, and even the final product quality of inorganic powder materials. It is far more than just a size number; it is the "master switch" of material properties.

1. Reflection of Processing Technology Level and Stability From large ore blocks to fine powders, complex processes such as crushing, grinding, and classification are required. The final particle size distribution directly reflects the advancement and control level of the production line process.

A powder product with a narrow particle size distribution (i.e., uniform particle size) and good repeatability indicates that the manufacturer possesses advanced grinding and classification equipment and strict process quality control, reflecting its technological strength.

2. Direct Determinant of Core Application Performance Particle size affects almost all aspects of powder performance, serving as a bridge between "material" and "function":

Specific Surface Area: The smaller the particle size, the greater the specific surface area (total surface area per unit mass of material). This directly affects:

Reactivity: In chemical and environmental fields (e.g., catalysts, adsorbents), a high specific surface area means more reaction sites.

Dispersibility and Wetting Properties: In coatings and inks, it affects stability and spreadability in the medium.

Sintering Activity: In ceramics and metallurgy, fine powders have lower sintering temperatures and produce denser products.

Filling and Packing Properties: A reasonable particle size distribution (a combination of coarse, medium, and fine particles) can achieve the densest packing, reducing porosity. This is crucial in concrete, refractories, and plastic fillers, improving strength and reducing resin usage.

Optical Properties:

Opacity (e.g., titanium dioxide): Opacity is highest when the particle size is half the wavelength of visible light (approximately 0.2-0.4 µm).

Gloss: For powders used in coatings and paper coatings, ultrafine and uniform particle size can form a smooth surface, producing high gloss.

Mechanical Properties: In composite materials (e.g., plastics, rubber), nano/micron-sized powders can play a reinforcing and toughening role; their particle size is directly related to the interfacial bonding strength.

Flowability: Particle size affects the angle of repose, conveying, and packaging performance of powders. Excessively fine powders are prone to agglomeration, resulting in poor flowability.

3. Key Benchmarks for Product Grading and Market Positioning The inorganic powder industry often uses particle size directly to define and differentiate product grades:

Ordinary Powder: Tens to hundreds of micrometers (µm).

Fine Powder: Several micrometers to tens of micrometers.

Micron-sized Powder: 1-10 µm.

Submicron-sized powders: 0.1-1 µm.

Nano-powders: < 100 nm.

Fineer particle size increases processing difficulty and typically yields higher added value, leading to applications in more advanced fields (such as electronic materials, biomedicine, and high-end coatings).