Antimony Trioxide: The Classic Synergist for Highly Effective Flame Retardancy-2

III. Applications

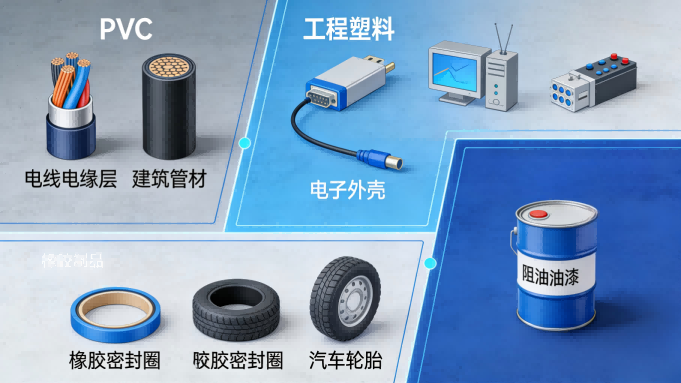

The antimony trioxide/halogen system is widely used due to its high efficiency and cost-effectiveness:

PVC (Polyvinyl Chloride): Wire and cable insulation, conduits, building materials. PVC contains chlorine intrinsically, so only a small amount of antimony trioxide is needed for good flame retardancy.

Engineering Plastics: Flame-retardant HIPS (High-Impact Polystyrene), ABS, PP (Polypropylene), PE (Polyethylene), etc., typically combined with brominated flame retardants. Used in electronic enclosures, connectors, and appliance components.

Rubber Products: Conveyor belts, cable sheathing, seals.

Textiles: For flame-retardant finishing of polyester and cotton fabrics (often as masterbatches or emulsions).

Coatings and Adhesives: In the formulation of fire-retardant paints and adhesives.

IV. Advantages and Limitations

Advantages:

High Synergistic Efficiency: Small amounts (typically 2-4 parts Sb₂O₃ with 6-12 parts brominated retardant) can achieve UL94 V-0 rating.

Cost-Effectiveness: Offers a lower overall cost to achieve equivalent flame retardancy levels.

Mature Technology: Long history of use with well-established processing knowledge and data.

Limitations and Environmental Concerns:

Environmental Impact: Faces restrictions under regulations like RoHS and REACH, especially when combined with certain brominated flame retardants (e.g., some polybrominated diphenyl ethers). Antimony trioxide itself requires careful management during production and disposal.

Effect on Material Properties: High loadings can degrade mechanical properties (e.g., impact strength) and cause opacity or color changes.

Health Concerns: Antimony trioxide is classified by the International Agency for Research on Cancer (IARC) as Group 2B (possibly carcinogenic to humans). Its dust poses potential risks to worker health.

Smoke and Toxicity: May contribute to increased smoke and toxic gas (e.g., carbon monoxide, hydrogen halides) generation during a fire.

V. Trends and Alternatives

With increasingly stringent environmental regulations and the rise of "green flame retardancy," the antimony-halogen system is facing challenges. Future directions include:

Halogen-Free Systems: Promoting alternatives like aluminum hydroxide, magnesium hydroxide, phosphorus-based retardants (e.g., DOPO derivatives), nitrogen-based retardants (e.g., MCA), and intumescent flame retardants (IFR). These are more environmentally friendly but often involve trade-offs in cost, loading requirements, and efficiency.

Nano-Sizing of Antimony: Using nano-antimony trioxide can achieve equivalent flame retardancy at significantly lower loadings, mitigating effects on material properties and reducing total antimony use.

Alternative Synergists to Antimony: Research into synergists for halogens such as zinc stannate, molybdenum compounds (ammonium molybdate, zinc molybdate), though their efficiency is generally lower than antimony's.

Conclusion

Antimony trioxide remains a cornerstone of practical, cost-effective flame retardancy, particularly for engineering plastics and PVC, thanks to its unparalleled synergistic performance with halogens. However, the evolving regulatory landscape and sustainability demands are driving the industry toward halogen-free solutions and technologies that reduce Antimony trioxide usage. For now, it continues to play a vital role, but its application is increasingly balanced with environmental and health considerations, guiding innovation toward next-generation flame retardant materials. Its story exemplifies the ongoing challenge in materials science: balancing optimal performance with safety and environmental responsibility.