The relationship between talc and carbon black

In the rubber industry, carbon black mainly plays a reinforcing role, and talcum powder is more used for filling. When the two appear in rubber at the same time, the combination of talcum powder and carbon black can also play a synergistic role to improve the various properties of rubber.

Rubber reinforcing filler

Reinforcing filler is one of the main raw materials in rubber industry.It can give rubber magnetism, electrical conductivity, flame retardancy and many other valuable properties, but also can greatly improve the mechanical properties of rubber, improve the service performance of rubber products, prolong the service life, and can improve the processing performance of rubber, reduce production costs.

Reinforcements used in rubber industry are mainly carbon black, white carbon black, silicate, carbonate, metal oxides and some organic matter.Their main role is to significantly improve the rubber tensile strength, tear strength, constant extension stress, wear resistance and other properties.

The fillers used in rubber industry are mainly inorganic fillers, such as talcum powder, clay, calcium carbonate, attapulgite, metal oxides and hydroxides.It can increase the volume, reduce the cost and improve the processing performance of rubber.

1. Carbon black reinforcing agent

Carbon black is made by incomplete combustion or pyrolysis of hydrocarbon compounds. It is mainly composed of carbon elements and exists in the form of colloidal primary particles and aggregates that are similar to spheres. The appearance is black powder.Generally processed into a diameter of 1~2mm granular products used.

Carbon black is the most important reinforcing agent in rubber industry and the second largest rubber material after raw rubber.At present, more than 90% of the world's carbon black consumption is used in the rubber industry.The dispersion degree of carbon black in rubber material affects its reinforcing property.The experimental results show that with the increase of carbon black dispersion, the constant tensile stress and Mooney viscosity of the compound decrease, the tensile strength and elongation at break increase, and the crack growth slows down.Therefore, improving the dispersion degree of carbon black in the rubber is the key to ensure the uniform texture of rubber and excellent performance of products.

2. Talc powder filler

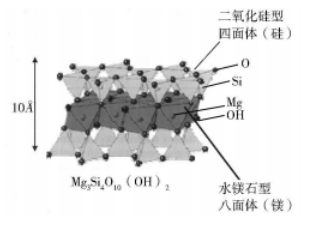

Talc powder is a kind of natural flake mineral.Pure talcum powder is composed of two silica sheets sandwiched with a brucite sheet composed of hydrous magnesium silicate, with a thin sheet shape.

As a filler, talc powder can be used to fill organic polymer materials, which can improve the rigidity, dimensional stability and lubricity of the products, prevent high temperature creep and reduce the wear on the forming machinery. It can not only improve the hardness and creep resistance of the polymer by filling, but also improve the heat-resistant impact strength of the polymer.It can improve the plastic forming shrinkage, bending elastic modulus and tensile yield strength.

Synergistic effect of talc and carbon black

Using talcum powder in carbon black reinforcing compound can improve the properties of the compound and the quality of the product.The effect of talcum powder and carbon black on the adhesive material is shown as the following seven points:

1. Rheological properties

By adding talcum powder to carbon vinyl, the viscosity of rubber is reduced, the in-mold fluidity is increased, the shrinkage of extruded material is reduced, and the calendering property is improved and the heat generation is reduced.

2. The reinforcement

Talcum powder is not only a filler, it is a reinforcing agent.The results show that the elongation of elastomer increases when talc is added to many carbon black elastomer adhesives.

3. Cut/tear resistance

Cutting a tensile specimen with a blade shows that talcum powder greatly improves the toughness and durability of the elastomer.At a relatively low elongation (<100%), the specimens reinforced by carbon black fracture completely, while the specimens reinforced by talc powder can continue to stretch.

4. Thermal performance

Talcum powder can improve thermal aging properties.This property is very important for rubber products that can withstand high temperatures, such as in the hood.

5. Low air permeability

Talc powder can reduce the permeability of carbon vinyl because the thin form can pose a barrier to the diffusion of gases and liquids.It is currently used in tire linings to reduce air transmittance.

6. Weather

Talc powder can reduce the carbon vinyl plasticizer volatilization, thus endowing excellent thermal stability and weather resistance, thus prolongs the service life of the product.It can limit the migration of by-products to the surface, reduce iridescent frosting and yellowing, and improve the gray level of automobile window seals.

7. Dispersion AIDS

Talcum powder is a kind of dispersing agent for reinforcing carbon black tire tread compound. It can improve the dispersing property of carbon black and other compounds and shorten the mixing time by 20%.In order to maintain the wear/abrasion resistance of the compound, the amount of talcum powder should be limited to 5 parts.