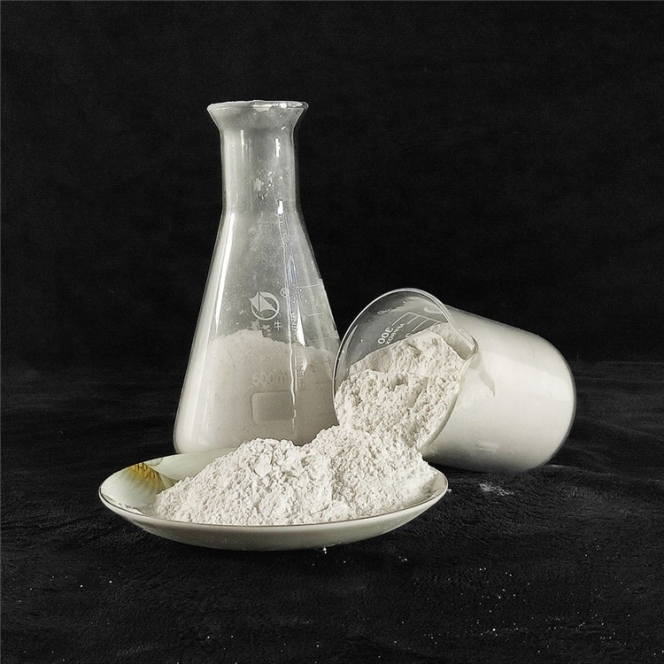

Surface treatment of magnesium hydroxide

Magnesium hydroxide Flame retardant is an inorganic flame retardant being actively developed at home and abroad. In addition to the above advantages of aluminum hydroxide, its thermal stability and smoke suppression performance are obviously better than aluminum hydroxide. Magnesium hydroxide dehydration occurs only when the temperature is above 350C, and the heat absorption of magnesium hydroxide is 17% higher than that of aluminum hydroxide, which also helps to improve flame retardant efficiency. At the same time, magnesium hydroxide is more suitable for polymers with high processing temperature. Thus it can be seen that different flame retardants have different characteristics and uses.

The surface of common magnesium hydroxide is hydrophilic and it is not easy to disperse in organic medium, and the mixed viscosity of magnesium hydroxide and organic medium increases sharply with the increase of its content in the mixed system. The surface of magnesium hydroxide modified by higher fatty acids (or its salts) is lipophilic, and it is easy to disperse in organic media, and the rising trend of mixed viscosity of magnesium hydroxide and organic media slows down greatly with the increase of its content in the mixed system.

Because the surface of magnesium hydroxide is weakly alkaline, the higher fatty acid ion reacts with the magnesium ion on the surface of magnesium hydroxide powder to form higher fatty acid magnesium which is attached to the surface of magnesium hydroxide powder. Because the alkyl group of higher fatty acid has affinity with the polymer, the agglomeration phenomenon of active magnesium hydroxide is inhibited, so the magnesium hydroxide modified by advanced fatty acid has good dispersibility in rubber and plastics.