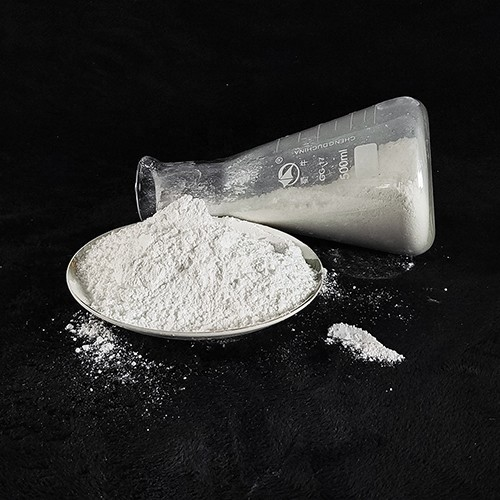

Nine elements of plastic selection of talc powder

1.The higher the purity of talc for plastic is, the better the enhancement effect is. Other mineral impurities in talc powder, metal minerals (especially iron) have a very obvious effect on the aging resistance of plastics.

2.Talc for plastic usually forms dense massive, leaf-like, radial, fibrous aggregates. Because the crystal structure of talc is layered, it has a tendency to split into scales and special lubricity. When talc for plastic is used in plastic products, it can be uniformly dispersed in layers and laminated in the resin, and it has good compatibility and complementary mechanical properties with the resin. Like the metal structure net embedded in cement products, it can form a reinforced support form with excellent mechanical properties in addition to maintaining the advantages of plastics, and can improve the physical properties of plastic products. Talc for plastic also has obvious heat preservation and barrier effect, which can not only reduce the production cost, but also improve the physical properties of plastic products.

3.The mixture of talc and plastic changes the color of the plastic more or less. Dark plastic products do not have high requirements for the whiteness of talc powder added. However, in order to make light-colored products have a better color, talc powder should have higher wet whiteness and suitable hue.

4.The SiO2 content in talc powder is an important index to measure the grade of talc powder. The higher the silicon content in talc powder is, the higher the purity of talc is, the better the application effect is, and the higher the price is. Customers need to choose talcum powder according to different performance requirements of plastic products.

5. The colors of raw talc are different from each other, and they can be white, gray, light red, pink, light blue, light green and other colors.

6. Talc for plastic presents different surface properties with different sources. Specific surface area and oil absorption rate are largely determined by mineral resources and product fineness.

7.The structure and morphology of talc for plastic determines its characteristics. Although talc powder is hydrophobic, because of the irregularity of the edge of its particle shape, it contains both structural water and crystal water, so the moisture content of talc powder is larger than that of calcium carbonate.

8. Talc for plastic has a layered structure with large specific surface area, the irregularity of particle shape and the convex and concave shape of the surface make it have a large friction coefficient and easy to produce static electricity, resulting in the agglomeration between small particles is difficult to disperse, affecting the application effect.

9. Fluidity in the extrusion process, the flake structure of talc powder is worse than other granular inorganic materials, it is difficult to disperse, and the main engine screw torque is large, so better activation coating is the key to overcome these problems.