Latest research: using gaseous silica to enhance the production and application performance of warm mix asphalt

Latest research: using gaseous silica to enhance the production and application performance of warm mix asphalt

In early June of this year, Swansea University recently published a study using fumed silica nanoparticles to enhance the properties of Warm mix asphalt (WMA). The results show that the material shows excellent potential in enhancing the moisture content and aging sensitivity of asphalt binder.

First of all, popularize science, through certain technical measures, so that the asphalt can be mixed at a relatively low temperature and construction, while keeping its performance is not lower than HMA asphalt mixture technology, also known as warm mix asphalt technology. The technical key is how to reduce the mixing viscosity of asphalt at lower temperature without damaging the road performance of HMA. At present, the international mainstream warm mixing technology is mainly realized by adding materials to reduce the high temperature viscosity of asphalt mixture. At the same time, the advanced technology of warm mix asphalt can completely make warm mix asphalt mixture to achieve the performance of hot mix asphalt mixture, but because of its lower mixing and compaction temperature, it has many advantages compared with hot mix asphalt mixture.

As an environmentally friendly and sustainable asphalt mixture technology, warm mix asphalt (WMA) has been widely paid attention to in the asphalt industry. Compared to conventional bitumen, WMA reduces steam and greenhouse gas emissions while reducing energy consumption during bitumen mixture production. However, high humidity sensitivity and asphalt aging reduce the durability of WMA on the road.

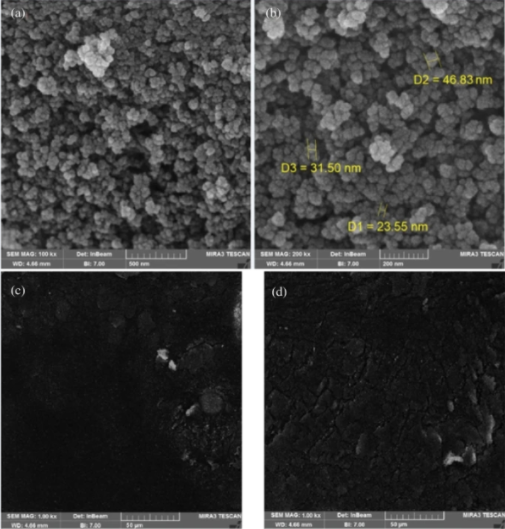

FESEM image of an adhesive modified by gaseous silica nanoparticles (FSN) at different magnification. The average particle size of FSN is 33 nm. A uniform hexagonal structure with an average diameter of 100-300 nm. FESEM images of FSN (a-c) without aging and (b-d) after aging modified adhesive.

To address two issues in WMA technology, the research team from the University of Swansea's Energy Security Institute (ESRI) and the Brunswick Centre for Road Engineering (ISBS) at the Brunswick Technical University found that vaporous silica nanoparticles (FSN) have the potential to be used as an anti-aging adhesive, not only to lower temperatures, And the temperature can be significantly lowered to overcome the limitations caused by susceptibility to moisture.

Lead researcher Goshtaps Cheraghian said: "The current study covers the gaps in WMA technology. The high specific surface FSNs are an economical and non-toxic material, which has an important influence on the shielding bitumen in WMA technology. In addition, our findings on the concept of molecular interactions between nanoparticles and asphalt binders could open up new avenues for the application of nanotechnology in asphalt engineering." Co-author Sajad Kian said: "It is possible that these high-surface area nanoparticles could one day be used in asphalt and to build more durable roads by reducing asphalt-related emissions (VOC and CO2) under realistic conditions."