Nanopowders and micropowders prone to agglomeration and instability? ALD ultra-thin coating offers the ultimate solution.

Atomic Layer Deposition Technology Provides Atomic-Level Precision Solutions for Surface Modification of Micro- and Nanopowders

Atomic Layer Deposition (ALD) technology originated in the late 20th century, initially successfully applied by Finnish scientists to the preparation of fluorescent materials such as ZnS and Mn, and Al2O3 insulating films, serving the flat panel display industry. Since the 1990s, with the rapid development of the semiconductor industry, ALD, with its unique advantages in thin film growth control, has quickly become an international research hotspot. After nearly thirty years of development, this technology has expanded from the semiconductor field to multiple cutting-edge areas such as catalysis, optics, and energy, and has gradually become one of the core methods for the preparation of functional thin films.

I. Technical Principles of Atomic Layer Deposition

Atomic layer deposition is a thin film growth technology based on sequential, self-limiting surface chemical reactions. It can achieve layer-by-layer, highly controllable material deposition on the substrate surface, unit by unit at the single-atom layer level. Its core mechanism lies in the self-terminating nature of each chemical reaction, ensuring that only one atomic or molecular layer is formed in each cycle, thus achieving nanometer-level or even atomic-level precise control of thin film thickness and composition.

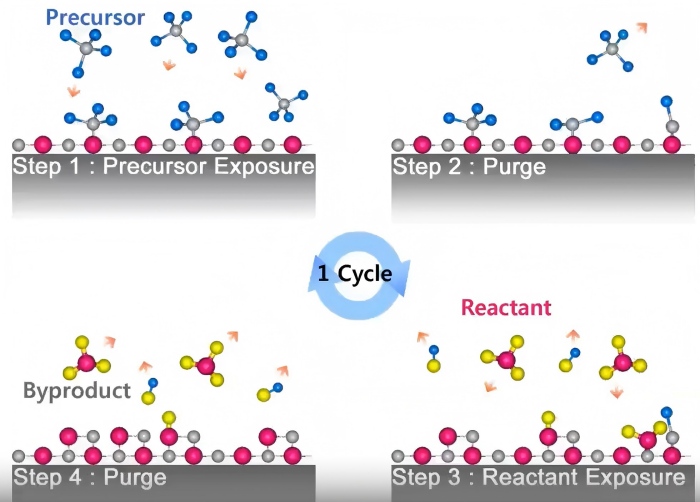

A typical ALD deposition cycle includes four steps:

Precursor A exposure: The first precursor vapor is introduced into the reaction chamber, undergoing chemical adsorption or reaction with the substrate surface until saturation forms a single adsorbed layer.

Purging: An inert gas is introduced to remove all unreacted precursor A and gaseous by-products from the chamber.

Precursor B exposure: The second precursor is introduced, reacting with the chemically adsorbed first precursor layer on the surface to form the target solid thin film layer.

Secondary purging: An inert gas is introduced again to remove excess precursor B and reaction by-products.

By repeatedly cycling through the above steps, the total number of deposition cycles can be precisely controlled, thus obtaining a uniform thin film of the desired thickness and properties.

II. Application Directions for Micro- and Nanopowder Modification

ALD technology, with its excellent conformality, uniformity, and thickness control capabilities, demonstrates unique value in the surface engineering of micro- and nanopowder materials. Main applications include:

Uniform Nanocoating: It can form a complete, pinhole-free coating layer on the surface of nanoparticles with complex shapes and high specific surface area. This ultra-thin film effectively prevents direct contact between particles and the environment (such as moisture and oxygen), preventing material degradation while maximizing the retention of the intrinsic properties of the core material.

Porous/nanostructured coating construction: Beyond dense encapsulation, ALD can also be used to construct functional nanocoatings on the surface or within porous materials, exposing active sites and regulating pore structures, showing great potential in catalysis, sensing, and energy storage.

Selective surface functionalization: By adjusting reaction parameters or utilizing surface chemical differences, precise modification and passivation of specific crystal facets, defects, or active sites of particles can be achieved, providing a powerful tool for atomic-scale design of material properties.

With industrial upgrading, high-performance micro/nano powder materials often face stability challenges while maintaining high activity. Furthermore, there is a growing demand for advanced structural materials with designable optical, electrical, and catalytic properties. ALD technology provides solutions for these needs, for example, by improving powder stability through ultra-thin protective layers, or by endowing materials with novel physicochemical properties through core-shell structures and heterojunction designs.