What is calcium carbonate filler used for?

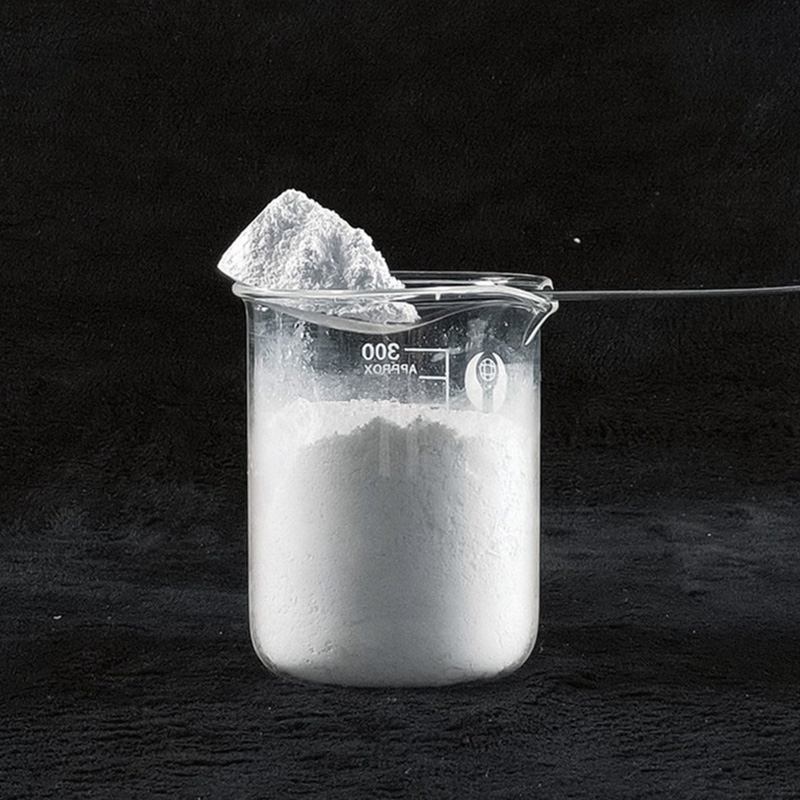

Calcium Carbonate Filler (CaCO₃) is one of the most widely used mineral fillers across multiple industries due to its cost-effectiveness, versatility, and ability to enhance material properties. It is derived from natural sources such as limestone, marble, and chalk, or produced synthetically through precipitation. Depending on the application, Calcium Carbonate Filler can be used in two primary forms: Ground Calcium Carbonate (GCC) and Precipitated Calcium Carbonate (PCC). Below, we explore its key applications, benefits, and industry-specific advantages in detail.

1. Plastics & Polymers Industry

Calcium Carbonate Filler is extensively used as a filler in plastic manufacturing to improve performance while reducing costs.

Key Applications:

PVC Products (pipes, cables, flooring, profiles) – Calcium Carbonate Filler Enhances rigidity, thermal stability, and impact resistance.

Polypropylene (PP) & Polyethylene (PE) (packaging films, containers) – Calcium Carbonate Filler Improves stiffness and reduces shrinkage.

Engineering Plastics – Calcium Carbonate Filler Used in automotive parts and electronic housings for better dimensional stability.

Benefits:

√ Cost Reduction – Calcium Carbonate Filler Replaces up to 20-30% of polymer resin, lowering material expenses.

√ Improved Mechanical Properties – Calcium Carbonate Filler Increases tensile strength and impact resistance.

√ Better Surface Finish – Calcium Carbonate Filler Enhances smoothness and printability in plastic films.

2. Paper Industry

CaCO3 Filler Masterbatch is a critical component in paper manufacturing, serving as both a filler and a coating pigment.

Key Applications:

Filler – CaCO3 Filler Masterbatch Added to the pulp to improve brightness, opacity, and printability.

Coating Agent – CaCO3 Filler Masterbatch Used in high-quality paper (magazines, brochures) for a glossy, smooth finish.

Benefits:

√ Enhanced Whiteness & Opacity – Reduces the need for expensive optical brighteners.

√ Cost Savings – Lowers fiber consumption, reducing production costs.

√ Eco-Friendly – Replaces kaolin clay in alkaline papermaking processes.

3. Paints & Coatings

In the paint industry, Powder Ground Calcium Carbonate acts as an extender pigment, improving performance while reducing formulation costs.

Key Applications:

Interior & Exterior Paints – Powder Ground Calcium Carbonate Enhances coverage, durability, and weather resistance.

Powder Coatings – Powder Ground Calcium Carbonate Improves flow properties and adhesion.

Industrial Coatings – Powder Ground Calcium Carbonate Used in anti-corrosive paints for metal protection.

Benefits:

✔ Improved Opacity & Whiteness – Reduces TiO₂ consumption (a costly pigment).

✔ Better Scrub Resistance – Increases the longevity of wall paints.

✔ Neutral pH – Compatible with both water-based and solvent-based formulations.

4. Rubber Industry

Powder Ground Calcium Carbonate is a key reinforcing filler in rubber products, improving strength and wear resistance.

Key Applications:

Tires & Automotive Parts – CaCO3 Filler Masterbatch Enhances abrasion resistance and durability.

Footwear & Rubber Sheets – CaCO3 Filler Masterbatch Improves flexibility and tensile strength.

Seals & Gaskets – CaCO3 Filler Masterbatch Increases compression resistance.

Benefits:

√ Cost-Effective Reinforcement – Reduces reliance on expensive synthetic rubbers.

√ Improved Processing – Enhances mold flow and reduces curing time.