Is talc a fire retardant?

1. Introduction to Talc and Fire Resistance

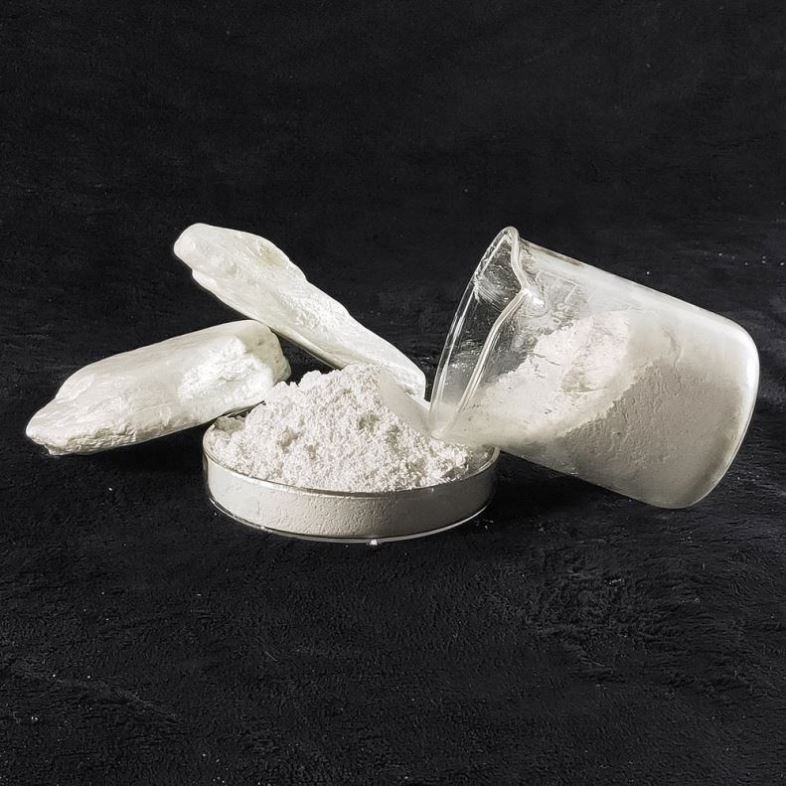

Cable Grade Talc Powder, a naturally occurring hydrated magnesium silicate (Mg₃Si₄O₁₀(OH)₂), is widely known for its softness, lubricity, and thermal stability. While it is not classified as a conventional fire retardant, Cable Grade Talc Powder exhibits several properties that contribute to fire resistance in certain applications. Unlike specialized flame retardants (e.g., halogenated compounds or phosphorus-based additives), Cable Grade Talc Powder primarily functions as a heat-resistant filler rather than an active flame suppressant. However, its thermal properties make it a valuable component in fire-retardant formulations.

2. Fire-Resistant Properties of Talc

(1) High Thermal Stability

Talc powder for Electric cable industries can withstand temperatures up to 900°C (1652°F) before undergoing decomposition, making it suitable for high-heat environments.

Unlike organic additives, talc does not combust, reducing fuel availability in fire scenarios.

(2) Endothermic Dehydration

When heated, Talc powder for Electric cable industries undergoes an endothermic reaction, releasing chemically bound water (from its hydroxyl groups).

This process absorbs heat, helping to delay temperature rise and slow flame spread.

(3) Insulating Barrier Formation

In composite materials,Talc powder for Electric cable industries particles can help form a protective layer that insulates against heat transfer.

This is particularly useful in polymers and coatings, where Talc powder for Electric cable industries improves fire performance without significantly altering mechanical properties.

(4) Low Thermal Conductivity

Talc Powder For Cable’s layered silicate structure contributes to low thermal conductivity, reducing heat propagation in materials.

3. Applications of Talc in Fire-Resistant Materials

Cable Grade Talc Powder is commonly incorporated into various industries to enhance fire resistance, including:

(1) Plastics and Polymers

Cable Grade Talc Powder Used in polypropylene (PP), polyethylene (PE), and PVC to improve heat deflection temperature (HDT) and reduce flammability.

Cable Grade Talc Powder Acts as a synergist with other flame retardants (e.g., aluminum trihydrate or magnesium hydroxide).

(2) Construction Materials

Added to fire-resistant boards, coatings, and sealants to improve thermal stability.

Used in intumescent paints (which expand under heat) to enhance char formation.

(3) Rubber and Cables

Cable Grade Talc Powder Improves heat resistance in wire and cable insulation, reducing flame spread.

(4) Ceramics and Refractories

Due to its high melting point, Cable Grade Talc Powder is used in kiln linings, firebricks, and heat shields.

4. Limitations of Talc as a Fire Retardant

While Cable Grade Talc Powder enhances fire resistance, it has some limitations:

Not a Standalone Flame Retardant – Talc Powder For Cable alone cannot meet stringent fire safety standards (e.g., UL94, ASTM E84) without additional additives.

Lower Efficiency Compared to Dedicated Retardants – Unlike aluminum hydroxide (ATH) or magnesium hydroxide (MDH), Talc Powder For Cable does not release large amounts of water to suppress flames.

Processing Challenges – High Talc Powder For Cable loading in polymers can affect mechanical strength and flexibility.

5. Enhancing Talc’s Fire Retardancy

To improve performance, Talc Powder For Cable is often combined with:

Metal hydroxides (ATH/MDH) – Provide additional endothermic cooling.

Phosphorus or nitrogen-based retardants – Enhance char formation.

Nanoclays or silica – Improve thermal barrier properties.

6. Conclusion

Talc Powder For Cable is not a primary flame retardant, but its thermal stability, endothermic behavior, and insulating properties make it a useful supplementary additive in fire-resistant materials. For applications requiring stringent fire protection, Talc Powder For Cable is typically used in combination with more active flame retardants.